In the ever-evolving landscape of industrial automation, efficiency and reliability stand as paramount objectives for manufacturers across various sectors. Recently, D&S, a renowned provider of automation solutions, proudly announced the successful delivery of a multi-pump automation system for a large beverage manufacturer. This innovative project showcases the fusion of advanced technology and expert engineering, promising enhanced control and monitoring capabilities for the manufacturing plant.

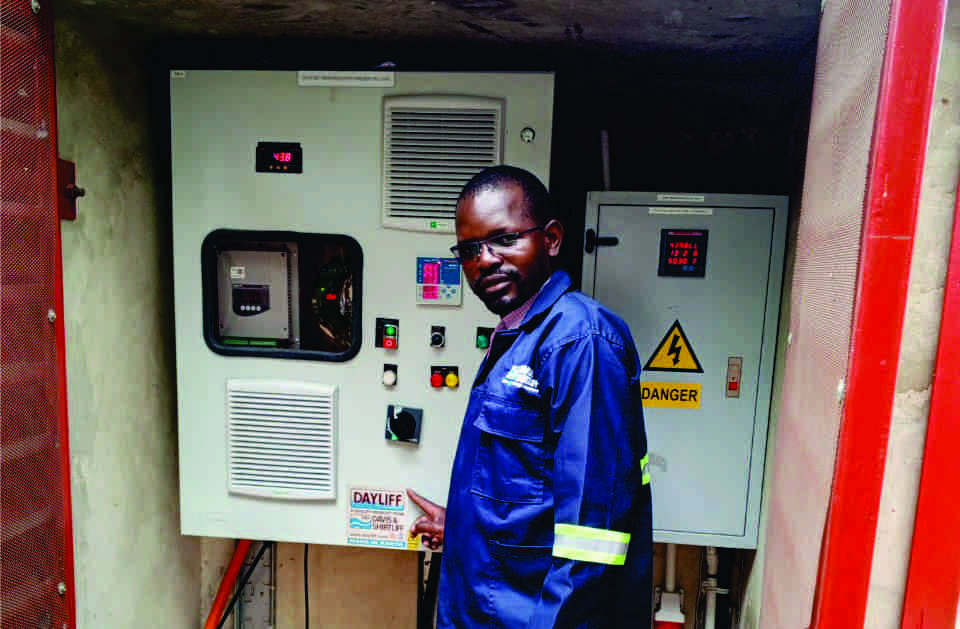

The heart of this automation system lies in the incorporation of Dayliff soft starter control panels, meticulously designed to optimize the performance of multiple pumps within the manufacturing facility. These soft starters offer precise control over the pump operation, ensuring smooth start-ups and efficient energy utilization. Moreover, they are equipped with advanced pump protection features, safeguarding against potential faults and minimizing downtime, a critical factor in high-demand production environments.

One of the standout features of this automation setup is the integration of the iDayliff IoT remote monitoring system. This technology enables real-time monitoring and management of the pump operations, providing plant operators with invaluable insights into performance metrics, operational efficiency, and potential issues. With remote access capabilities, stakeholders can oversee plant operations from anywhere, facilitating proactive maintenance and swift response to any anomalies.

A crucial aspect of any automation project is the post-installation phase, where thorough inspections ensure optimal functionality and adherence to performance standards. Field Engineer Kennedy Owitchira, pictured during a routine post-installation inspection, exemplifies the dedication and expertise driving D&S's commitment to customer satisfaction. Through meticulous attention to detail and comprehensive testing procedures, engineers like Owitchira ensure that the automation systems deliver on their promise of reliability and efficiency.

The significance of this multi-pump automation project extends beyond mere technological advancements. By streamlining operations and enhancing control capabilities, the beverage manufacturer stands to benefit from improved productivity, reduced operational costs, and heightened competitiveness in the market. Furthermore, the integration of IoT-based monitoring underscores a broader industry trend towards smart manufacturing, where data-driven insights drive informed decision-making and operational excellence.

As industries continue to embrace automation as a cornerstone of modern manufacturing, partnerships with trusted solution providers like D&S become increasingly invaluable. By leveraging state-of-the-art technologies and domain expertise, D&S empowers manufacturers to navigate the complexities of production environments with confidence and agility. The successful implementation of the multi-pump automation system for the beverage manufacturer exemplifies the transformative potential of innovative solutions in optimizing industrial processes.

In conclusion, D&S's delivery of multi-pump automation for the beverage manufacturer represents a significant milestone in the journey towards smarter, more efficient manufacturing practices. With advanced control panels, pump protection features, and IoT-enabled monitoring capabilities, the plant is poised to achieve new levels of productivity and operational resilience. As industries embrace the era of Industry 4.0, such collaborations pave the way for a future where technology and human expertise converge to drive sustainable growth and innovation.